Advantages of FRP Reinforcement in Seismic Construction

Fifty years ago engineering community possessed little knowledge and practical experience in designing structures and buildings able to withstand tremendous forces and stresses of even a moderate earthquake, let alone a powerful one. They also lacked innovative materials which would provide effective reinforcement alternative to traditional metal and cement products.

Consequently, a vast majority of buildings, bridges and other structures, designed and constructed prior to the mid-1980’s, are unsafe and easily compromised when an earthquake happens. Such design and construction deficiencies are further highlighted by the significant instances of older structures collapsing or sustaining severe damage during recent earthquakes.

From the early to mid-1990s, there has been a growing utilization of FRP (Fiber-Reinforced Polymer) materials within the construction sector. By the early 2000s, FRP reinforcement materials emerged as a credible substitute for steel, leading to a substantial rise in their incorporation across construction projects.

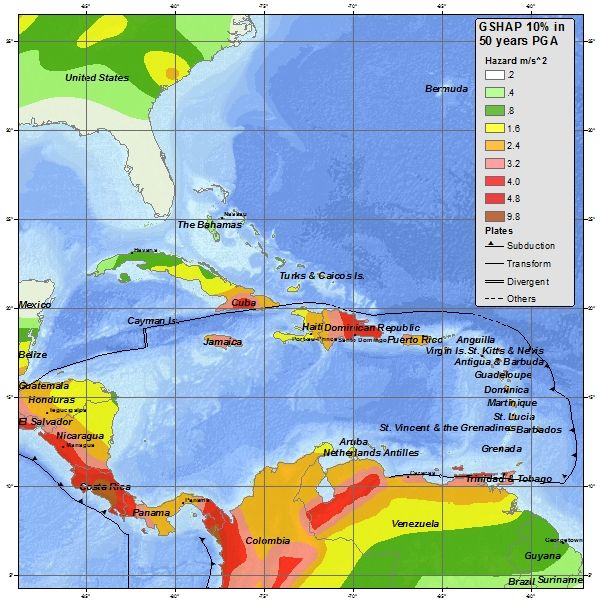

Therefore, it comes as no surprise that there is a considerable amount of ongoing research worldwide focusing on new construction techniques and retrofitting existing structures within seismic activity zones. This research primarily revolves around the utilization of FRP concrete reinforcement products, including rebar, mesh, and fibers. It has been found that FRP materials can be effectively and economically used in retrofitting floors, walls and columns of buildings to enhance their axial, flextural and sheer capacity.

While the world’s leading engineering and construction standards organizations have not yet issued official standards and codes specifically for seismic zone construction involving FRP materials, overwhelming evidence indicates that FRP, particularly GFRP (Glass Fiber-Reinforced Polymer), is highly suitable for such applications. The increasing popularity of FRP reinforcement over traditional steel stems from its ability to enhance structural ductility and exhibit crucial characteristics such as:

Superior Strength: FRP exhibits exceptional tensile and flexural strength (usually 2x vs steel), making it highly resistant to the forces exerted during an earthquake.Lightweight: FRP is lightweight (5x-7x lighter than steel), reducing the overall structural weight and allowing for easier transportation and installation.Corrosion Resistance: Unlike steel, FRP is not susceptible to corrosion, reducing structural compromise, prolonging the lifespan and reducing required maintenance of structures in seismic regions.Flexibility: The inherent flexibility of FRP enables structures to deform without catastrophic failure, enhancing their seismic performance.Better Crack Control: FRP reinforcement, together with fiber-reinforced concrete, offer enhanced crack resistance vs steel reinforcement by better distributing the tensile stresses generated during an earthquake and resisting the formation and propagation of cracks. This superior crack control not only increases the overall strength and durability of the structure but also enhances its resistance to further seismic events.Non-Conductivity: Binevir FRP reinforcement products are non-conductive electrically, magnetically or thermally, which makes them less prone to related detrimental influence

If you’re involved in designing, constructing, or even just contemplating projects in seismic activity Zones 2, 3, or 4, we highly recommend reaching out to ANI to explore our top-tier composite reinforcement materials and products. Our expertise and best-in-class solutions could greatly enhance the safety and resilience of your structures in earthquake-prone areas.