SuperFiber®

When it comes to Fiber Reinforced Concrete (FRC) the options are plentiful and choosing the right option can be confusing, even for the experienced construction professionals. In making the right fiber choice, one must first consider the intended purpose of concrete reinforcement. There are generally two types of concrete reinforcement in engineering specifications:

- Primary – Structural (load carrying), and

- Secondary – Temperature and shrinkage (cracking, thermal expansion and contraction)

Primary concrete reinforcement is generally achieved with the use of various rebar and mesh options. While traditional fiber reinforcement can aid in enhancing load-bearing properties of concrete, it is usually not selected as a sole option for Primary reinforcement, especially in high-load applications.

Fibers are an excellent choice, however, as a secondary concrete reinforcement, as they increase strength and durability, minimize shrinkage and expansion with temperature fluctuations and reduce cracking and crack propagation.

But which fibers do you chose for your project? There are steel fibers, composite micro fibers (monofilament and fibrillated, OD ≤ 0.01″/0.3 mm),various macro fibers (OD > 0.01″/0.3 mm), plastic fibers, just to mention a few. While most fibers are designed to achieve similar property enhancements in concrete, many have different advantages and disadvantages, required mix volumes, mix-in rates and finishing requirements. Wouldn’t it be great if there existed a ubiquitous concrete reinforcing fiber that could be effectively deployed in most applications, including those requiring primary reinforcement? BINEVIR has created such a fiber.

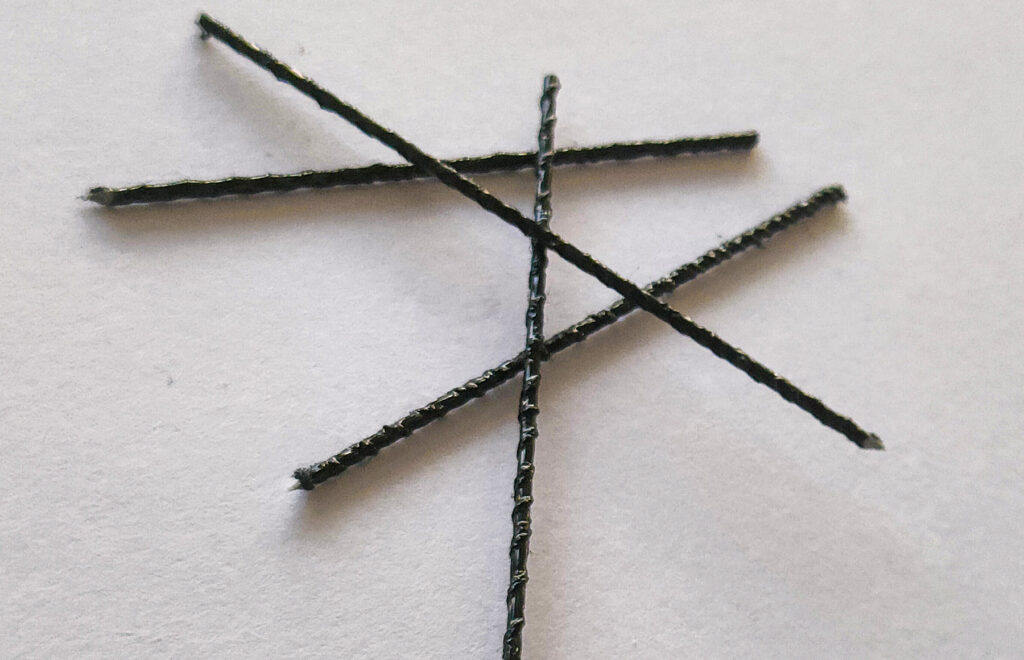

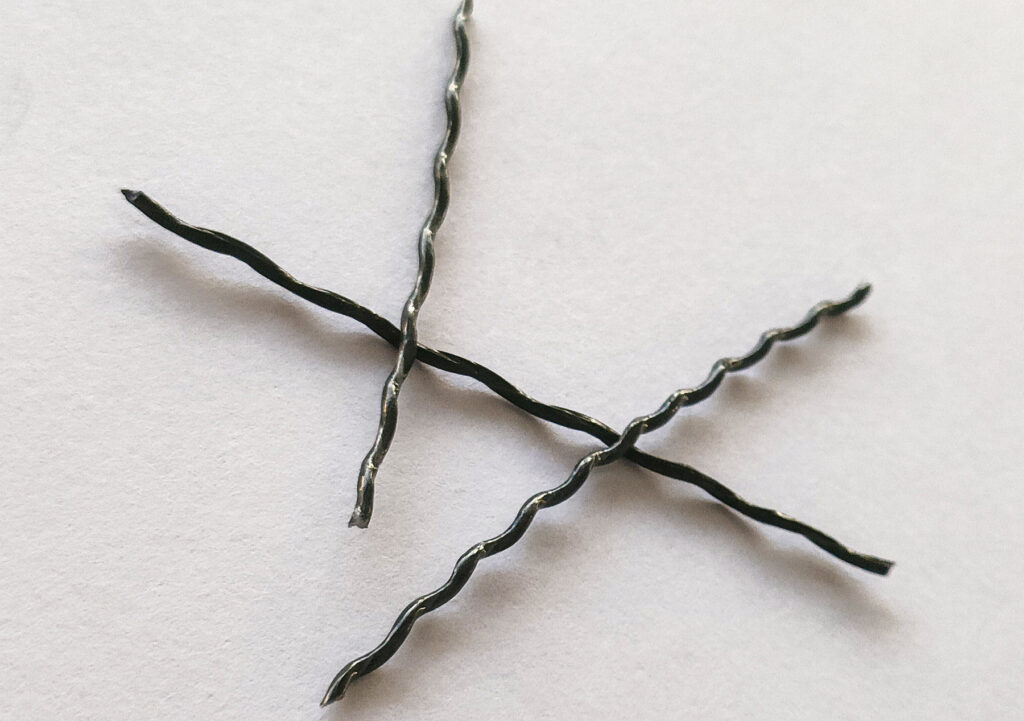

BINEVIR SuperFiber® is a new type of composite fiber for concrete reinforcement, designed to be the perfect additive to almost any concrete design and application. It is a high-performance high-aspect-ratio engineered fiberglass macrofiber which:

- Disperses homogeneously throughout the concrete mix

- Will not ball up, clump, or sink in most concrete mixes

- Does not affect the use of admixtures

- Does not retain air

- Will not swell up or absorb any of the moisture from the concrete mix

- Is fully non-corrosive, even in the high-salt marine environments

- Is highly resistant to alkali and other chemicals

- Can be added to dry and wet cement mix, pre-mixed or on-site

BINEVIR SuperFiber® can be successfully used to replace steel fibers, welded wire mesh and conventional reinforcing bars in a wide variety of applications with similar or better results.

BINEVIR SuperFiber® is compliant with ASTM C1116, “Standard Specification for Fiber Reinforced Concrete and Shotcrete”, ASTM C1609/C1609M-12 “Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete” and is specifically designed to provide equivalent tensile and bending resistance to conventional reinforcement requirements. Concrete reinforced with BINEVIR SuperFiber® will have three-dimensional reinforcement with enhanced tensile strength, flexure toughness, durability, energy absorption, impact and abrasion resistance and will help mitigate many forms of cracking in concrete due to plastic shrinkage. While it is often impossible to completely eliminate concrete cracking, adding BINEVIR SuperFiber® to concrete mix can be highly effective in increasing the residual flexural strength of concrete, keeping the material together if and when the cracks do appear, even in the extreme load-intensive installations and in demanding salt, thermal and chemical environments. This will ensure the extended and worry-free life of your project, while dramatically reducing required post-installation repair and maintenance.

Dosage rates for BINEVIR SuperFiber® in concrete will vary based on the specific reinforcing requirements of the project and can range from 34 to 68 lbs/yd³ (15.4 to 30.8 kg/m³).

** It is always important to verify the project design specifications and adherence to applicable codes and guidelines when a replacement of the steel or composite rebars with the BINEVIR SuperFiber® is contemplated.**

Applications of Binevir SuperFiber®

- Slab-on-ground/grade (including pile-supported)

- Precast concrete applications

- Shotcrete applications

- Foundations for commercial and residential buildings

- Water channels, ponds, marine construction

- Roads and driveways

- Parking garages

- Retaining walls

- Hybrid reinforcement (rebar/mesh + fiber)

- Industrial floors and roads

- Seawalls, bridges, overpasses

- Concrete fences

- Flat works

- Decorative casting

- Repair and retrofit projects

- Many more